Over the last decade, Fulcrum Acoustic has made its way in the pro audio world, developing a reputation for its loudspeakers, approach to design and customer service. When company president Stephen Siegel teamed with David Gunness (industry legend/VP, R&D) and Chris Alfiero to found the company in 2008, it was another step in Siegel’s lifelong journey through pro audio. It also was incredibly bad timing, as the Great Recession kicked in almost immediately. That’s the kind of unexpected calamity that will test the mettle of any fledgling company, but for Siegel, the answer was to keep moving forward.

“My interest in audio dates back to my high school days, when I toyed with PA gear owned by the various bands I was playing in,” he recalled. (In fact, he’s still a keyboard player for several bands around Rochester, NY.) Nonetheless, Siegel’s real introduction to pro audio came in the early 1980s through the Recording Institute, a program offered by the University of Rochester’s Eastman School of Music.

“I was an electrical engineering student at the University of Rochester, studying saxophone at Eastman, and the Recording Institutes were summer programs taught by industry luminaries,” he said. “There, I learned about many aspects of recording, room acoustics, disc production/mastering, audio electronics and sound reinforcement. This opened my eyes to a number of audio-related fields, each with its own career possibilities. I found the topics related to live performance to be the most interesting; this is what sparked my interests in acoustical design and sound reinforcement system design.”

Related: View from the Top on Pro Sound News

For the rest of his college career, Siegel worked at the Eastman studios during the school years and summers, handling recording, mixdowns, editing and sound reinforcement duties. That real-world experience laid the groundwork for the next 14 years as he became an acoustics and audio system design consultant. In time, he joined the engineering team at EAW, where he worked to innovate and deliver creative solutions for a variety of applications.

That, in turn, paved the way for co-founding Fulcrum Acoustic. “Today, at Fulcrum Acoustic, we have tremendously talented and experienced teams in all aspects of the business,” he said. “My role as president of the company is to work with each team to plan and guide our growth. I manage the sales, marketing, admin and manufacturing teams; that’s not as daunting a task at it may seem, as we have experienced staff in place in each department.”

Those departments aren’t necessarily under one roof, however, as some Fulcrum Acoustic personnel are spread out across the country, though the main office is in Rochester, NY. Case in point, Todd Foster, director of North American sales, works in Memphis, TN, while Jon Sager, the western regional sales manager, is based in Southern California. “It’s remarkably easy to stay in close communication through IM, VoIP and other similar tools,” said Siegel. “While we do have enough of a corporate structure to provide the necessary framework for the company, we strive to let everybody do what they do best without excessive overhead. Overall, it’s a pretty informal and creative atmosphere; it’s the way we enjoy working.”

Related: Purdue Football Performance Complex Gets Pumped with Fulcrum Acoustic, Pro Sound News, Feb. 8, 2018

Some of the company’s most creative efforts can be found in the realm of R&D, based in Massachusetts, albeit only a mile away from Fulcrum Acoustic’s separate manufacturing facility. “David Gunness manages the R&D and product development efforts,” said Siegel. “He receives input from the sales team and customer base, and merges those requests with technologies that he’s working on to deliver innovative solutions. He’s an amazing innovator and has assembled a design team that is always working on interesting products and technologies.”

When the company was founded, those solutions were sometimes pretty varied, but that’s changed with time. “David Gunness, Chris Alfiero and I started Fulcrum in February of 2008—and six months later, the world economy collapsed,” said Siegel. “That forced us to shift gears a bit. In those early days, we ping-ponged between strategic product design/planning and grabbing opportunities that presented themselves.”

Since then, the company has found firm footing and has developed a substantial product line in the intervening years. “Now that we are larger and have a technology base under our belt, we can better balance strategic and opportunistic efforts with a bit less frenzy,” he said. “Presently, Fulcrum’s product line is installation-focused, with a few portable products to help round out the line. We have been fortunate to have success in a number of important markets; our most typical projects are worship, theme park, sports facilities, performing arts and club/hospitality. Lately we have been experiencing a surge of interest in our reference monitors for production and post-production facilities. Additionally, our subwoofers and full-range systems incorporating the Passive Cardioid feature are becoming quite popular.”

Key to Fulcrum Acoustic making its way in the marketplace has been the company’s effort to ensure its product line is “inherently differentiated from the competition. Our broad selection of coaxial products allows designers to develop solutions based on ultra-compact loudspeaker systems. Our AH series of high-output, high-sensitivity systems allows for reduced amplifier size and channel count, thereby reducing costs associated with amplifiers and wiring. One of newest developments, Passive Cardioid, provides for extended LF pattern control without additional cancellation drivers and their associated electronics and wiring. All of these technologies—plus others—help us provide a unique set of tools in a competitive industry.”

Related: Fulcrum Acoustic Brings Big Sound to Texas High School Mega-Stadium, Pro Sound News, Jan. 22, 2018

Another focal point for the company has been its dedication to providing customer support. Stating that it is “an important part of the Fulcrum culture,” Siegel pointed out that most members of the company’s sales and engineering teams are also called on to provide support in one form or another. “We are fortunate to have exceedingly experienced staff,” he said. “Collectively, we have probably worked on almost every conceivable project type at one time or another. We draw on this experience often when supporting our customers and their projects.”

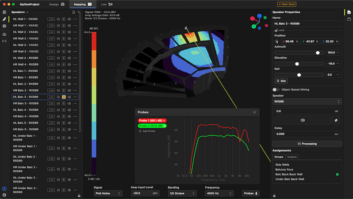

Siegel further broke down the support into two specific areas: design and after-sale. “Design support includes product selection and suggestions for ancillary gear like amplifiers and DSP. We pride ourselves in supporting as many third-party electronics products as possible to give our customers maximum flexibility. Then, after-sale support might include tuning suggestions, warranty support, troubleshooting guidance and so on.”

While the loudspeaker manufacturer has evolved considerably over the last decade, Siegel doesn’t see its evolution as complete, and that forward-focused mindset is shared throughout Fulcrum Acoustic. “As a technology-driven company, we are always experimenting with better ways to solve sound reinforcement challenges,” he shared. “We continue to evolve our Passive Cardioid tools, as these provide compelling performance benefits; you will see future Fulcrum products that incorporate this feature. Beyond that, we’ll just wait and see.”

Fulcrum Acoustic • fulcrum-acoustic.com