By Ilpo Martikainen and Will Eggleston

In principle, a three-way speaker offers clear sonic benefits, especially at higher sound levels, due to a separate midrange channel. If these benefits are desired, the designer must choose between a small enclosure with no directivity control (and hence strong dependence on the listening environment) or a larger enclosure, where proper directivity control can be included. The technical dilemma lies in the physical dimensions available for proper MF and HF directivity control.

Since the introduction of the 1022A in 1985, Genelec has approached this issue with waveguides, called DCW (Directivity Control Waveguide), having spaced mid and tweeter drivers. DCW has proven to be a successful concept in the professional market. With the aim to develop a smaller three-way product with limited physical dimensions, Genelec’s traditional waveguide simply had insufficient space. The development started for a new coaxial driver, which would combine a MF/HF waveguide for directivity control. Coaxial drivers are by no means new, but the novelty is in eliminating the inherent response problems associated with their structure.

Coincident-source loudspeakers provide advantages over spaced drivers, especially at the crossover region. Improvements in imaging, response and directivity can be achieved. The basic principle of a coaxial driver is to place the HF driver at the apex of the LF diaphragm. Doing so, the apparent source location does not depend on frequency, and the directivity of both drivers may be controlled in the crossover region. Furthermore, coaxial technology utilizes less front panel space than comparable designs with spaced drivers.

Although conventional coaxial designs provide several advantages, they also present drawbacks. The woofer cone movement causes inter-modulation and Doppler distortion to the tweeter radiation. The larger the cone displacement, the more inter-modulation will be produced. The directivity, although improved at the crossover, may not be uniform at higher frequencies. Also, most current common midrange/tweeter driver constructions have inherent acoustic discontinuities, which show as uneven on-axis HF response.

The common challenge in all coaxial designs is how to avoid the said acoustical discontinuities and their effects on the response. Diaphragms have to move—there have to be gaps—but sound is easily diffracted from such discontinuities, and so on, resulting in a somewhat uneven response.

The Genelec MDC Solution

The first step is to minimize the cone displacement—in other words, to limit the low frequency bandwidth of the driver. This is both trivial and simultaneously important for the accepted solutions. Avoiding the sources of diffraction is a bit more complicated. The solution resulted in several ideas, some of which are now in the MDC (Minimum Driver Coaxial) driver.

The main structure of the MDC design consists of an integrated MF diaphragm–suspension–tweeter construction. The visible part of the coaxial driver is formed by the curved flexible skin with the dome tweeter assembly in its center. The inner section joins the cone to the tweeter without any acoustical discontinuity, and the outer one does the same between the cone and the driver chassis. As there are no acoustically observable discontinuities between the tweeter and the cone, just a smooth surface, there is no diffraction either. The cone profile is very carefully optimized to form an integrated directivity control waveguide for the tweeter radiation. The driver outer edge is terminated to a normal Genelec DCW in order to control the dispersion of midrange radiation as well.

The system looks surprisingly simple and tidy. This development in coaxial design improves imaging and overall sound quality. The response is very smooth (see Fig 1), both on- and off-axis, and, free from any anomalies and directivity, is well controlled.

Besides providing more sound pressure than the 8000 series 2-ways, the 8260A combines, for the first time, a coaxial driver (MDC) within a modern waveguide (DCW), ensuring drivers couple coherently over their full operating bandwidth as well as being single MF/HF coincident point source.

Housing and DSP

The 8260A breaks new ground in electro-acoustic system thinking, as mechanical, acoustical and signal processing designs are intimately linked together. Following the current Genelec 8000 practice, the 8260A uses a curved die-cast aluminum enclosure, with the benefits of an increase in internal effective volume, improved heat dispersion, inherent rigidity, improved LF efficiency and extended LF cutoff (26 Hz (-3 dB) for the 8260A). The Genelec IsoPod vibration isolation stand, which also allows vertical tilt for aiming, is integral to the design.

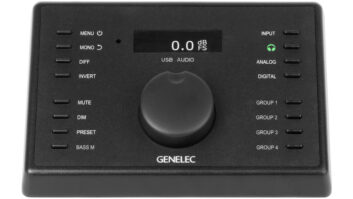

The DSP hardware is an extension of, and complete redesign (with performance improvements) of the 8200 series DSP–a true three-way, which implies that the driver feed signals for the tweeter, midrange and woofer are all fed into their respective DA converters, then to power amplifiers (also newly designed), and then finally onto each drive unit. The DSP processor in the 8260A contains all basic loudspeaker functions, such as the crossover filters, driver equalization, driver position alignment, and all the room alignment-related filters, such as the room response equalizers and propagation delay correction. The parametric notch and shelving filters can be set automatically using the AutoCal automatic room alignment process built in to the GLM (Genelec Loudspeaker Management) software. Unlike the rest of the 8200 series, there will be no 8000 series analog only version of the 8260A

The 8260A loudspeaker system represents Genelec’s cutting-edge innovations in all technology domains. Also, the electronic domain (hardware and software) of the system benefits from the 8200 Series design advancements. The MDC coaxial MF/HF breakthrough solution makes the loudspeaker unique in the market.

This combination results from years of R&D effort and investment, as well as sound tacit competencies behind the 8260A product. Such breakthrough solutions cannot happen quickly, but are rather results of long-term persistent and solution-oriented research and development work.

Ilpo Martikainen is CEO/co-founder at Genelec OY and Will Eggleston is Genelec U.S.’s marketing director.